Application:

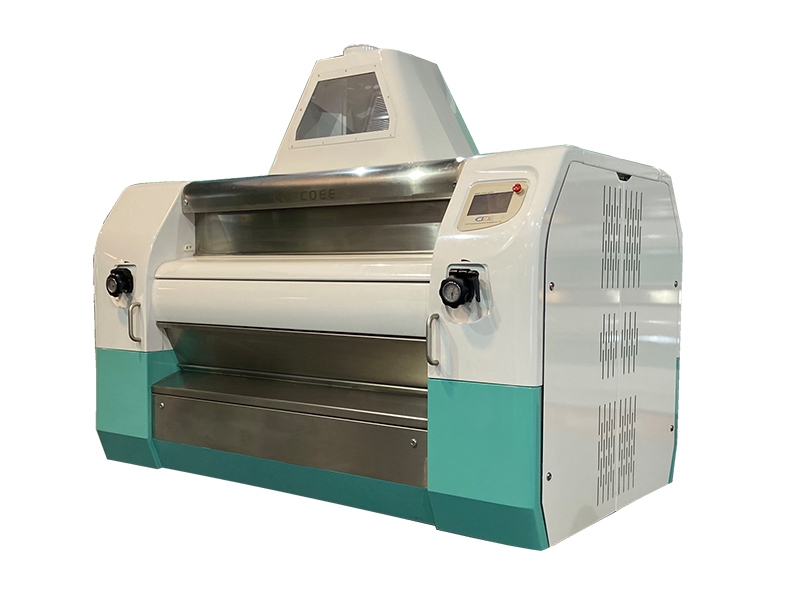

The roller mill is the main equipment for milling section in flour mills. It mainly depends on a pair of differential transmission and relative rotation rolls to break wheat, meanwhile, scrapes endosperm from wheat bran, then endosperm grinding into flour. The material can be extruded, sheared and broken during the equipment working and so as to achieve a certain grinding effect, each roller mill has two independent drive, feeding, and grinding systems and play their functions in the flour passages.

Features:

1)Use lever principle and patent measuring sensor technology to convert material flow changes into digital signals. Then use intelligent servo control technology to adjust material door size and feeding roller speed in order to ensure uniform feeding and achieve stable grinding, reduce roller damage and reduce power consumption.

2)Feeding unit is designed as independent modules with hatchback rolling and quick clean functions. It also meets food hygienic requirements.

3)Front panel is turned integrally which can achieve quick roller disassembling.

4)Material contact part is made of one-time forming food-grade stainless steel structure with no dead angle and no residue. This ensures the safety of food hygiene.

5)Ribbed belt is elastic tension device. It can automatically compensate the trace of transformation, improve the service life of the belt.

6)Easy fine-tuning rolling structure. Small cylinder lock handwheel panel buttons control is convenient and fast.

7)Combine industrial appearance and modern mold technology to realize overall streamlined appearance design. Won the national patent of appearance.

MMT Main Technical Parameter:

|

Item |

Unit |

Specification |

||||||||

|

Model |

|

MMR25/1250 |

MMR25/1000 |

MMR25/800 |

|

|||||

|

Roll Diameter×Length |

mm |

ø 250×1250 |

ø 250×1000 |

ø 250×800 |

|

|||||

|

Diameter Range of Roll |

mm |

ø 250 — ø 230 |

||||||||

|

Fast Roll Speed |

r/min |

450 — 650 |

||||||||

|

Gear Ratio |

|

1.25:1 1.5:1 2:1 2.5:1 |

|

|||||||

|

Feed Ratio |

|

1:1 1.4:1 2:1 |

|

|||||||

|

Half Equipped with Power |

Motor |

|

6 grade |

|||||||

|

Power |

KW |

37、30、22、18.5、15、11、7.5、5.5 |

||||||||

|

Main Driving Wheel |

Diameter |

mm |

ø 360 |

|||||||

|

Groove |

|

15N(5V) 6 Grooves 4 Grooves |

|

|||||||

|

Working Pressure |

Mpa |

0.6 |

|

|||||||

|

Dimension(L×W×H) |

mm |

2060×1422×1997 |

1810×1422×1997 |

1610×1422×1997 |

|

|

|

|||

|

Gross Weight |

kg |

3800 |

3200 |

2700 |

|

|

||||